PRODUCTS

Search by Keyword

Search by Item No.

This kind of bags can keep components sensitive to static away from the potential static danger to the largest extent. Its special faraday electric cage structure can create such effect as an inductive cover to separate the goods inside from the static field.

Excellent performance

Farady cage constructed,the barrier shielding to protect the protected prodct safety.

Lining low rate of resistance.

Anti-static features outstanding, electrostatic field slowly, the safety of relief.

High mechanical strength design, and free from damage, to recycling materials smooth, feel comfortable.

Easy opening, a substantial increase production efficiency.

Aesthetic appearance

Accept 2 colors printing

Production capacity

5 automated production lines and 20 sets related equipments.

Convenient for all orders' or OEMS orders' production,fast delivery

General shielding bag length:3" to 40" width:2" to 40"

Zipper bag shielding length:5" to 18inch width:3" to 30"

|

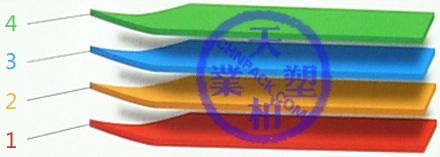

| 1.Anti-static polythene or Anti-static polystyrene(optional) |

| 2.Polyester |

| 3.Metallized layer |

| 4.Anti-static polyester |

| No. | Item | Unit | Norm |

| 1 | Metallized layer resistance |

Ohm/sq | <100 |

| 2 | Metallized layer Light tarnsmission |

40%-0.4 | |

| 3 | Surface resistivity | Ohm/sq | <1011Ω |

| 4 | Time for static removal | 5000-0V | <0.01second 101BMethod 4046 |

| 5 | Friction Static | ELA541 Appendix C avg | Triboelectric Nsnocouiombs Quartz <13n°/in2 Tefion < 1313n°in2 |

| 6 | Capacitance probe | EIA541 | <10V |

| 7 | Anti-erosion | No visible spots, FTMS 101 Method 305 | |

| 8 | Tensile strength | Lbs./ in | >18 |

| 9 | Tear initiation | Lbs./ in | >2.5 |

| 10 | Puncture resistance | P.S.I | >100 |

| 11 | Seam strength | Lbs./ in | 8 |

| 12 | MVTR barrier | gm/ 100in -2/24hrs | <0.2 |

| 13 | Oxygen barrier | CC/ 100in-2/24hrs | <0.5 |

| 14 | Heat sealing temperature | F | 250-375 |

| 15 | Heat sealing time | S | 0.5-3.5 |

| 16 | Heat sealing pressure | P.S.L | 70 |

| 17 | surface resistivty | Ω | 10-10 Ω |

| 18 | Externals | No lamination defects,no blistering, crack-free | |

| 19 | Standard thickness | mil | 3/4 |

PE bags

PE bags